Silica brick for glass kiln

Classification:

Key words: refractory material

Product Details

use of glass kiln silica brick:

It is used for the crown, heat storage chamber and breast wall of glass melting furnace.

Features of high quality glass kiln silica brick:

1, high purity raw materials: select high purity (SiO >99%), low impurity content, hard and dense crystalline silica as the raw material of the product.

2, the product square quartz obvious: to the main crystal phase of the silicon brick load softening start temperature as high as 1690 degrees C, close to its refractoriness, as a glass kiln brick, there are more significant advantages. In addition, the high purity structure of cristobalite gives cristobalite-type silica bricks a higher erosion resistance than other silica bricks; moreover, the low content of residual quartz gives silica bricks a good volume stability, thereby prolonging the service life.

3. Low melt index: The melt index (Al₂ O 2R O) is an important indicator for characterizing high-quality glass kiln silica bricks at high temperature. Low melt index is good for high temperature resistance.

4, good appearance size: high firing temperature and long firing insulation time, to ensure the full conversion of crystal type. The electronic batching system controlled by the microcomputer fully guarantees the accuracy of the batching and the stability of the particle size distribution, so the size of the produced products is accurate.

5. Good on-site pre-assembly capability: Our company has a high-quality technical team, which can decompose and design drawings. The professional on-site combination team has rich practical experience. The assembled glass kiln arch, liquid flow hole, neck and other parts are well received by users.

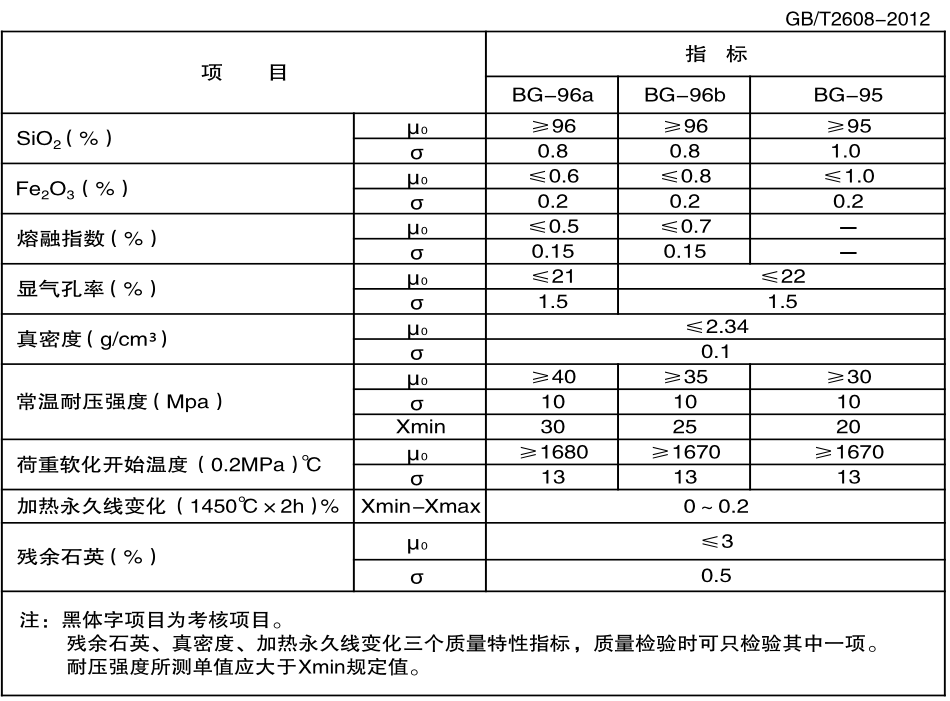

Physical and chemical indexes of silica brick for glass kiln